This article was reprinted from Yeah!Legend Blog:

At present, CNC flame and plasma cutting machines begin to be widespread among manufacturing enterprises in China. In order to improve production efficiency, expand production scale, many companies began to purchase and use CNC cutting machines. Due to lack of concepts and knowledge of CNC cutting, these companies would suffer technical problems and using difficulties when purchasing and using CNC cutting machines. Here is an article, introducing ways of purchasing or selling CNC cutting machines.

Simply, CNC cutting machine contains three parts:

一、Machine Tool

二、CNC System

三、Optimized Nest Software

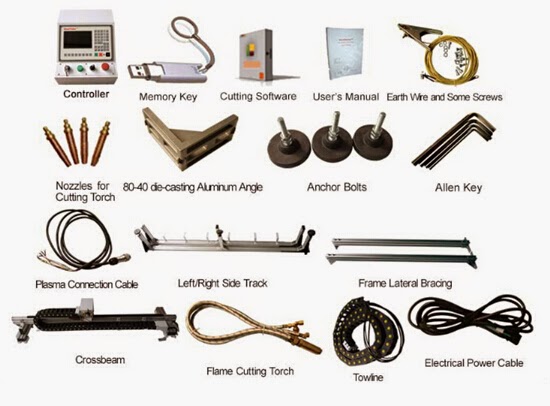

1. Machine tool is the main body of CNC cutting machine, including crossbeam and guide rail, rack/gear wheel drive system, reducer, servo motor system, air circuit system, lift system, electric control cabinet, along with THC system, automatic ignition system, scoring system, cooling system, etc. Quality and processing precision of machine tool, purchase of key component (reducer, servo drive, THC, etc.) are important parts that will influence functional allocation, lifespan of machine tool, cutting quality and precision.

2. CNC system plays an important role as chief commander of CNC cutting machine. It mainly contains an industrial controller and a set of software specialized for CNC cutting and cutting controller software. The hardware configuration of industrial controller in CNC system determines the steady of CNC cutting machine and CNC system. Cutting control software in CNC system offers all kinds of cutting skill and motion control mode, determining the cutting efficiency and cutting quality of CNC cutting machines.

3. Optimized nest software is the necessary tool for efficient use of CNC cutting machine. Its key functions are as follows, 1. centralized nest of components and steels, especially the whole plate optimized nest and rest plate optimized nest, effectively improving the use ratio of steel plate nest. 2. Nesting programming and cutting efficiency. Through automatic and manual interactive fast nesting, automatic programming and efficient cutting technologies, working efficiency of nesting programming and cutting efficiency have been improved greatly.

Three main features of a CNC cutting machine:

1. Be able to cut certain plate with specific material and thickness, serving for specific products;

2. Be able to improve cutting efficiency and cutting quality;

3. Be able to save steel plate and consumables effectively.

How to choose specific type and equipment of CNC cutting machine? According to cutting materials and thickness, requirement for cutting efficiency and cutting quality, company could firstly select the type of CNC cutting machines, such as flame, plasma, laser or CNC groove cutting machine. Secondly, company should get to know the efficient pierce capacity and pierce technology in order to ensure the specific equipment of CNC cutting machines, such as types of plasma power, flame torch and preheat cutting oxygen equipment or CNC groove cutting method. Therefore, the equipment of CNC cutting machine and price can be settled.